Final Design for the improvement of the potabilization system of Novi Ligure (AL)

| Approx. value of the construction cost (in current US$):

US$ 2.029.131,00 Approx. value of the contract (in current US$): US$ 15.500,00 |

| Country: Italy.

Location within country: Novi Ligure, Province of Alessandria, Piemonte Region. |

| Name of Client:

Gestione Acqua S.p.A. |

| Start date (month/year): December 2019

Completion date (month/year): February 2020 |

| Name of associated Consultants, if any: None |

Description of actual services provided by your staff within the assignment:

KEYWORDS: concept; detailed design; potabilization; drinking water plant; revamping; screening; fast mixing; Flocculation; MBR; disinfection.

- Use of the best available technologies (Best Available Technologies, BAT) in the field of water treatment.

- Plant design to respond to customer treatment requests, guaranteeing high standards potabilization yields and refining the quality of the final product from a microbiological and turbidity.

- Introduction of technical solutions aimed at minimizing the system’s energy consumption and reducing the dosage reagents.

- Choice of machines characterized by high performance, reduced energy consumption and low noise.

- Creation of works perfectly inserted in the surrounding area, in order to minimize the visual impact.

Description of Project:

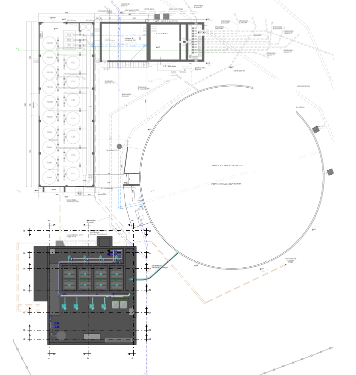

The new treatment phases were divided as follows:

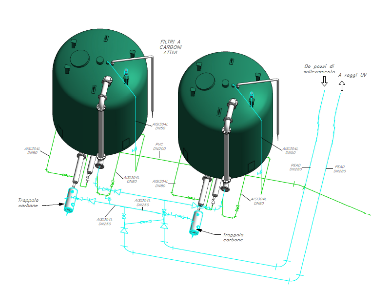

- insertion in the existing tank where all the wells of a dosing system meet of coagulant and a mixer, as well as a 0.5 mm protective filtration.

- the creation of a flocculation tank between the filter shed and the existing tank.

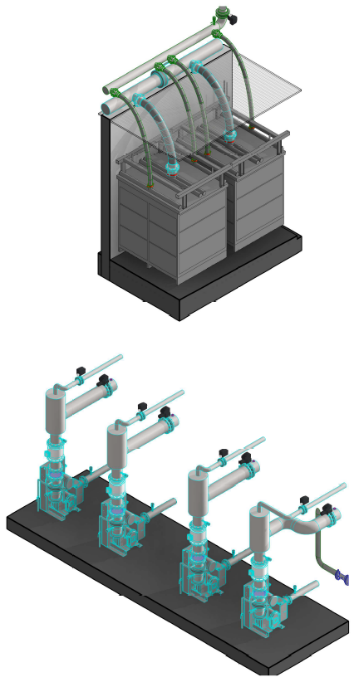

- construction of a new shed where to install the trains of immersed membranes for the water treatment.

- the creation of an underground pipe for the disposal of the sludge produced during the drinking water process.