Technical and economic study for the realization of “East Peja” wastewater treatment plant in the Municipality of Peja

| Approx. value of the contract (in current US$):

US$ 3.804.531,20 |

| Country: Kosovo.

Location within country: East Peja. |

| Name of Client:

Municipality of Peja |

| Start date (month/year): January 2017

Completion date (month/year): May 2017 |

| Name of associated Consultants, if any: None |

Description of actual services provided by your staff within the assignment:

KEYWORDS:

Feasibility Study, data collection, wastewater treatment plant design; Primary treatment, initial lifting station, biological treatment, chemical precipitation, final disinfection, mechanical sludge dewatering station.

Description of Project:

- Definition of the data framework based on the resulting sizing checks from the analysis of the catchment areas served and the consequential polluting loads to be subjected to treatment and some design assumptions in terms of temperatures and qualitative limits to be guaranteed by the effluent at the discharge;

- Description of the hypothesized treatment chain;

- Results of the pre – sizing checks of the various treatment sectors;

- Rough estimate of the construction and management costs.The two treatment plants have been named “East Peja” and “Rugova Region” WWTP.

- Based on the data collected and considering that the trend of the resident population in the area in recent years is not estimated to be growing, the total catchment area to be served was considered as a precautionary measure of 22.000 inhabitants.The design potential of the new wastewater treatment plant was therefore assumed to be equal to 22.000 PE.

- The treatment chain hypothesized for the “East Peja” treatment plant is the following:

- sewage arrival;

- coarse screening with automatic cleaning and drain of any excess flow rate, equipped with automatic activation filtration system in case of overflow activation;

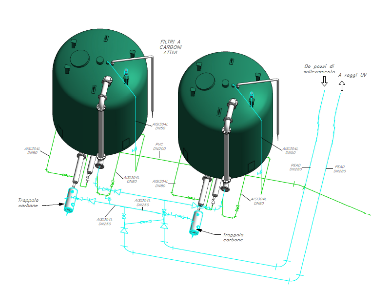

- initial lifting station, equipped with 3 + 1R submersible centrifugal pumps;

- two fine screening channels operating in parallel;

- aerated sand – de – oiling basin with longitudinal flow;

- a distribution well to the biological treatment lines;

- two biological treatment lines with activated sludge, structured according to the predenitrification / nitrification scheme;

- a flocculating reagent dosing station for the simultaneous removal of phosphorus by chemical precipitation, with dosing in the distribution well at the entrance to the biological treatment;

- a well for the distribution of the flow to the secondary settlers;

- two secondary sedimentation basins with a circular radial flow plan;

- a final disinfection channel by chemical oxidation by dosage of sodium hypochlorite or peracetic acid;

- a static thickening basin of the excess mud;

- an aerobic digestion tank;

- a mechanical sludge dewatering station.