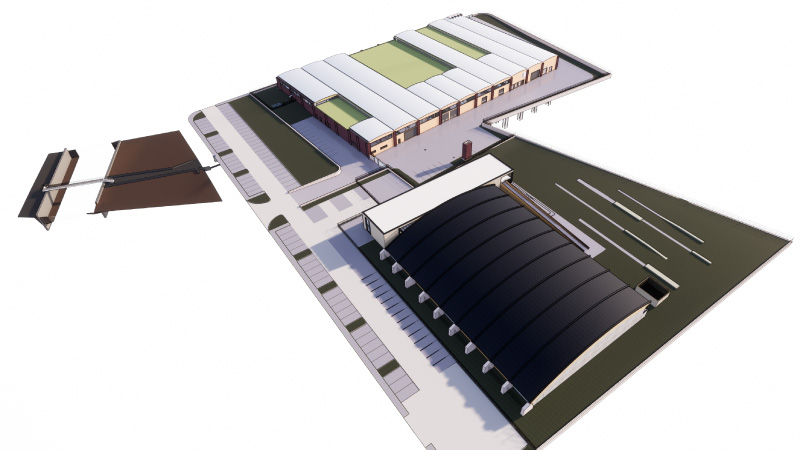

The project is aimed at ensuring the wastewater treatment generated by the territorial area in question through a single centralized treatment plant realized with modern and advanced technologies, thus guaranteeing a greater level of effectiveness, efficiency and cost-effectiveness than can be take place with the management of several plants located in different areas. Currently the territory is served by two separate plants which are not adequate to respect the limits for discharge into surface waters. The new plant is characterised by a potentiality variable between 46.000EA and 70.000EA.

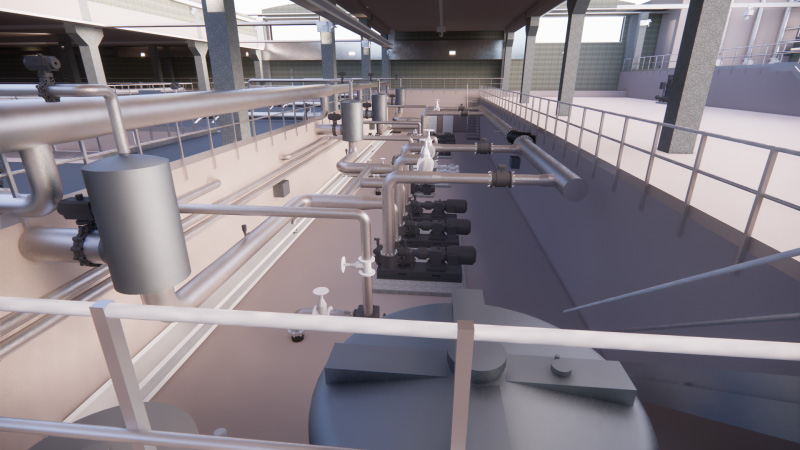

The Ramaia MBR plant is located entirely inside a shed. The water line treatment chain consists of:

– sewage arrival pipeline from the new sewage lifting station;

– coarse screening station;

– fine screening station;

– sandblasting-deoiling section;

– flow divider to the biological treatment lines, with an automated by-pass system for discharging the excess flow rate Qpb = 3 ∙ Qm;

– four secondary treatment lines with MBR technology operating in parallel, consisting of:

– n. 4 biological treatment lines configured according to the pre-denitrification / nitrification scheme;

– n. 1 common channel for collecting and distributing the sludge to the filtration cells;

– n. 4 membrane ultrafiltration cells;

– n. 2 deoxygenation tanks, each equipped with 2+1R pumps for lifting the sludge to the recirculation channels at the head of the biological treatment;

– n. 1 permeate accumulation tank with function of lung during the membrane washing operations;

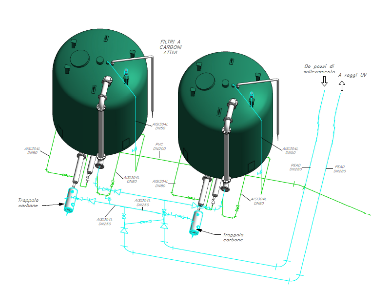

– a 40% ferric chloride solution dosing station for simultaneous chemical dephosphating, with injection into the distribution channel to the biological lines;

– a 30% sodium hydroxide solution dosing station for any pH correction, with entry into the distribution channel to the biological lines;

– a compartment for final disinfection of the effluent by UV irradiation;

– an accumulation tank for the treated effluent;

– effluent discharge system. This project also involves the construction of the emergency discharge collector at the Gromolo stream.