Project for the adaptation and upgrading of the Cicognolo (CR) Wastewater Treatment Plant.

Approx. value of the contract (in current US$): US$ 57.386,84 Approx. value of construction cost (in current US$): US$ 827.072,00 |

Country: Italy. Location within country: Cicognolo, Province of Cremona, Lombardia Region. |

Name of Client: Padania Acque S.p.A. |

Start date (month/year): November 2021 Completion date (month/year): February 2022 |

| Name of associated Consultants, if any: None |

Description of actual services provided by your staff within the assignment:

Preliminary and detailed Design

KEYWORDS: upgrading, discharge limits, intermittent ventilation, optimization. Evaluation of the existing conditions, Current criticality, and planned interventions;

Description of Project:

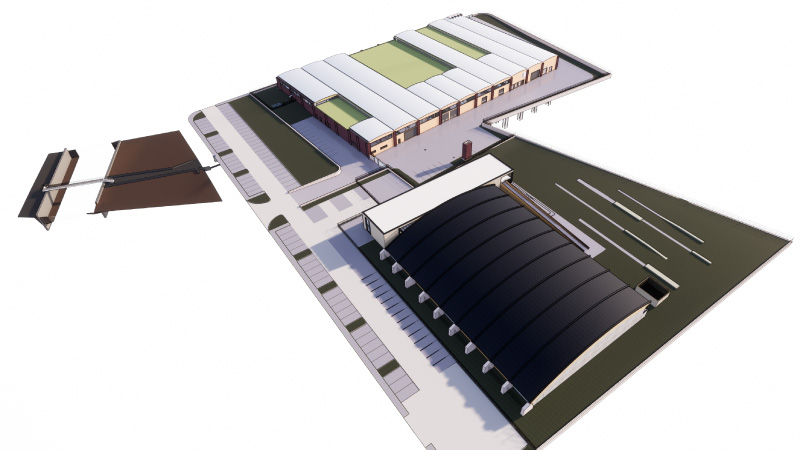

The project to upgrade the Cicognolo WWTP aims that the water deriving from the town of Pescarolo will be additionally conveyed to the plant. Therefore, the project potential will increase from 1200 PE to 3000 PE. The analysis showed the need for a treatment chain able to comply with the discharge limits with reference to total suspended solids, ammoniacal nitrogen and organic material concentration. Specifically, the planned interventions can be summarized as follows:

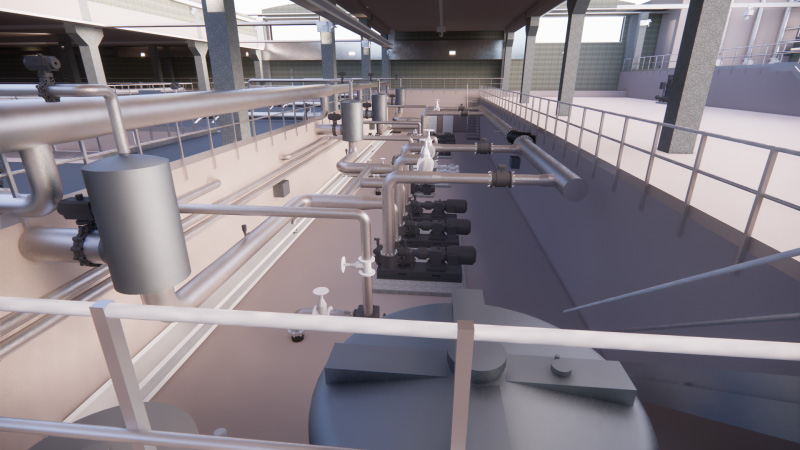

- Adjustment of lifting from slurry arrival sump to pre-treatment: replacement of initial lifting pumps to raise the maximum design flow rate attributable to pre-treatments which, is Qpm=2250 m3/d=94 m3/h. There was the related adjustment of the pipes, adjustment of regulation artifacts and insertion of the flow meter, insertion of instrumentation for level control so as to interface the logical operation of the pumps;

- Insertion of fine grilling: insertion of a new metal carpentry gallery on which to place the new fine grid provided with 2mm holes;

- New sand removal sector: realization of civil work in reinforced concrete housing the new track sand trap served by two gates one at the entrance and one at the exit, installation of a new blower dedicated to the extraction of sand with air-lift system;

- Realization of the splitter for the biological lines: new flow allocator obtained within the new biological compartment in order to distribute the flow rate on the two lines that make up the new product of the organic sector;Realization of a new biological compartment: composed of a new reinforced concrete tank separated by a central septum to separate the biological department into two lines for the convenience of any maintenance operations. The total useful volume of the two lines is about 650 m3 equally distributed over the two lines. It was decided to insert a biological compartment with intermittent ventilation to optimize the process, energy costs and the surface occupied. The construction of a new compressor room is planned;

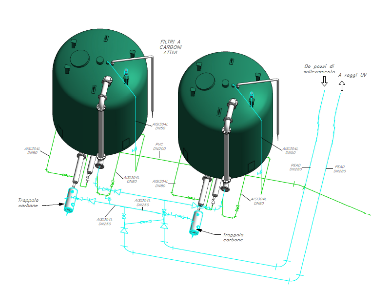

- New secondary sedimentation plant: with a useful volume of about 300 m3 with a circular plan with an adjoining sludge well to manage recirculation and excess flows;

- New static thickening structure: demolition of the current thickening well given the insufficient volume for an effective thickening of the sludge, it was decided to build it new to optimize the planimetric configuration and the new static thickening with reinforced concrete artifact will be realized; Final discharge connection from the current exit product; Demolition of drying beds and sludge accumulation well; Demolition of the calm septum of the existing sedimentation artefact;