Upgrading of the Verziano Wastewater Treatment Plant.

| Approx. value of the construction cost (in current US$):

US$ 109.536.068,59 Approx. value of the contract (in current US$): US$ 847.1997,19 |

| Country: Italy.

Location within country: Verziano, Province of Brescia, Lombardia Region. |

| Name of Client:

A2A Ciclo Idrico S.p.A |

| Start date (month/year): December 2020

Completion date (month/year): September 2021 |

| Name of associated Consultants, if any: None |

Description of actual services provided by your staff within the assignment:

Feasibility Study, Preliminary Project

KEYWORDS: upgrading, increasing the treatment capacity, upgrading the water line and the sludge line, activated sludge process chain, tertiary final filtration.

Description of Project:

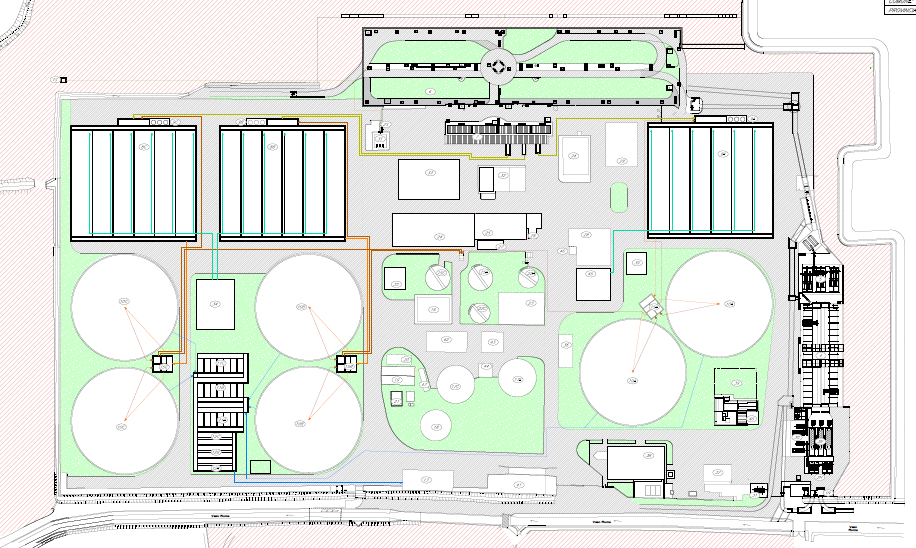

The project of technical-economic feasibility of the intervention has the objective of increasing the treatment capacity of the purifier to the project potential of 400,000 AE by upgrading the water line and the sludge line of the plant according to the greater incoming polluting loads foreseen. The Verziano treatment plant has, in its current configuration, a theoretical potential of 296,000 AE. The planned works concern only the area contained within the current boundaries of the plant, providing for the demolition of existing buildings and the construction of new compartments. The intervention is also divided into distinct construction phases in order to ensure the continuity of treatment of the wastewater delivered to the purifier throughout the duration of the works.

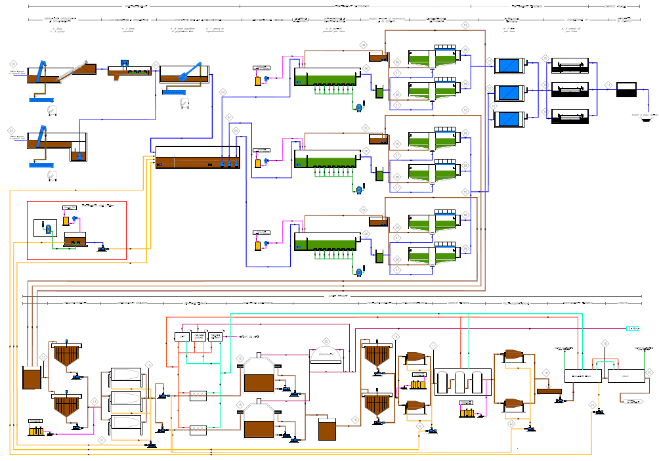

This project provides for an increase in the overall potential of the plant to 400,000 AE, which will be achieved with the following interventions:

- the gradual decommissioning of the existing treatment lines and the construction of 3 new parallel treatment lines, each with a project potential equal to 133,333 PE and consisting of an activated sludge process chain characterized by aeration nitrification / denitrification reactors intermittent, secondary sedimentation with sludge recirculation, tertiary final filtration treatments and UV disinfection.

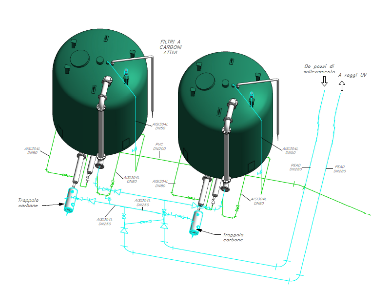

- the adaptation and upgrading of the sludge line of the plant, through the reconstruction of the anaerobic digesters, the adaptation of the biogas line (including the construction of a new gasometer), the introduction of a thermal hydrolysis treatment of the sludge with the aim to optimize the energy self-production from biogas and to reduce the quantities of dehydrated sludge produced thanks to the increase in the degree of dryness obtainable, the creation of a side-stream treatment for the abatement of ammoniacal nitrogen content in the flow of recirculated mother liquors in the water line