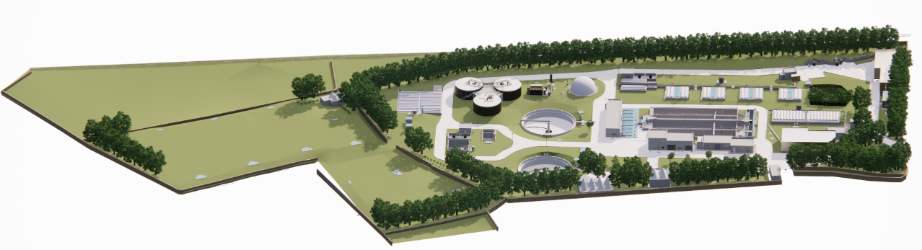

Executive project for the upgrading and adaptation of the treatment plant serving the agglomeration of Martina Franca (TA)

| Approx. value of the construction cost (in current US$):

US$ 8.664.109,23 Approx. value of the contract (in current US$): US$ 131.927,50 |

| Country: Italy.

Location within country: Martina Franca, Province of Taranto, Puglia Region. |

| Name of Client:

Faver S.p.A. |

| Start date (month/year): January 2020

Completion date (month/year): May 2020 |

| Name of associated Consultants, if any: None |

Description of actual services provided by your staff within the assignment:

- Executive design in integrated contract;

- Introduction of improved technical solutions compared to the final project

- adoption of technological solutions for the water line similar to those already used at the other treatment plants in the area and which guarantee the receipt of peak flows even double the average flow rate in dry weather,

- introduction of technical solutions aimed at minimizing the energy consumption of the plant and reducing the production of waste

- adoption of measures for the management of emergency situations and anomalous flows;

- provision of accumulations for the rates of purified water that cannot be conveyed to the final delivery;

- complete confinement and deodorization of the gaseous effluents of the new works and compatibility of the latter with the local landscape.

Description of Project:

The upgrading of the plant is aimed at satisfying future treatment needs, with project polluting and hydraulic loads determined starting from an analysis of the current state and the extent of future connections envisaged, in compliance with the provisions set forth by the legislation and by the instruments current planning rules in terms of quality requirements for discharge and maximum flow rate to be started for treatment. As per the forecasts of the PTA of the Puglia Region, the project potential of the plant is set at 59288 PE. At the same time, construction of works that can be exercised flexibly, even in the presence of loads lower than those of the project.

WATER LINE:

-Definition of the covering structures of the recently built screening and primary treatment sections,

– Optimize the control and management of the biological treatment compartment by installing various packages of the OSCAR® advanced process controller,

– Definition of the hydraulic configuration of the membrane filtration compartment that exploits the gravity feed of the membranes from the biological compartment,

– Installation of new lobe compressors for the air supply,

– Construction of a new driveway inside the plant around the biological treatment tanks,

– New effluent storage tanks for internal reuse as service water and possible future external reuse with UV disinfection treatment.

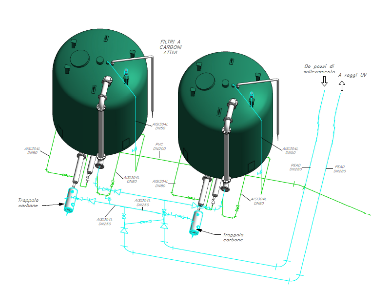

SLUDGE LINE:

– Preparation of a screening system instead of thickening the primary sludge,

– Construction of a new anaerobic digestion section for sludge stabilization,

– Installing the advanced OSCAR® Dewatering controller.