Adjustment interventions on the Mantua plant to comply with discharge limits and to be able to treat the flow rate in rainy weather

| Approx. value of the construction cost (in current US$):

US$ 19.384.641,10 Approx. value of the contract (in current US$): US$ 205.000,00 |

| Country: Italy.

Location within country: Mantova, Province of Mantova, Lombardia Region. |

| Name of Client:

TEA S.p.A. |

| Start date (month/year): May 2019

Completion date (month/year): July 2020 |

| Name of associated Consultants, if any: None |

Description of actual services provided by your staff within the assignment:

- introduction of technical solutions aimed at minimizing maintenance and the possibility of suspending treatment and placing the plant in reserve, restarting it as needed;

- choice of machines characterized by high efficiency, low energy consumption and low noise;

- Biowin modeling of the current plant for problem analysis;

- Analysis of all phases of the transient both from the point of view of the process and from the electrical point of view to guarantee the maximum possible service; Drafting of documents required by the Lombardi Regional Regulation to ensure hydraulic stability and to obtain the necessary authorisations;

- comparison tables to highlight the works subject to demolition and the works close to those subject to new construction, useful for the purpose of analyzing the transitory;

- Use of BAT in the field of hygienic-environmental engineering.

Description of Project:

The project is aimed at adapting the treatment plant to the regulatory requirements that have occurred in order to improve the treatment processes and achieve higher treatment yields. The plant has had several adjustments since the beginning, structurally and in optimizing processes. The capacity of the new plant is 100,000 EA which allows for the treatment of the additional load to which the plant would be subject.

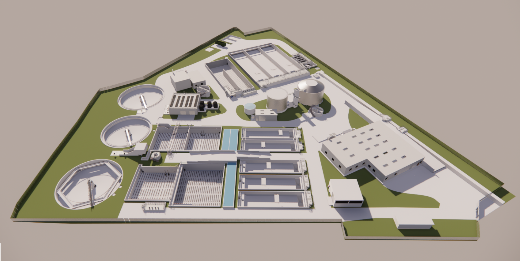

The water line treatment chain is composed of:

– Inlet pipeline of the sewer system; 6 mm grilling, consisting of three vertical continuous belt grilles;

– Circular aerated sand trap; Five identical longitudinal flow primary sedimentation compartments;

– An equalization tank with a useful volume of 2000 m3; Four biological oxidation tanks for carbon removal and nitrification, managed through the OSCAR® process controller – Intermittent aeration;

– Chemical co-precipitation of phosphorus by dosing of ferric chloride; three radial flow secondary settlers;

– A 500 m3 volume chlorination tank of clarified effluent. The treatment chain of the sludge line consists of:

– A pre-thickening tank with a diameter of 6.6 m (120 m3);

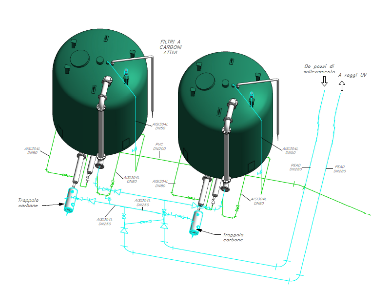

– A two-stage anaerobic digester;

– A post-thickener with a diameter of 7.8 m (220 m3);

– A mechanical dehydration compartment with centrifuge, after chemical conditioning.

– of the sludge with a polyelectrolyte solution prepared in a special preparation plant.